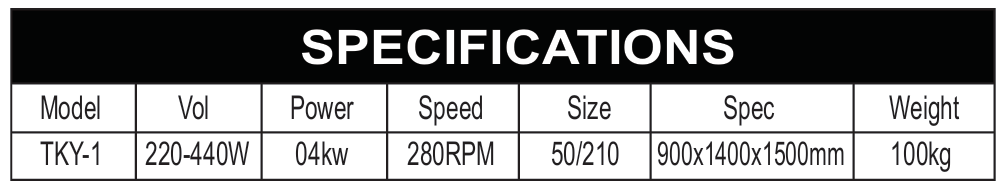

The TKY-1 Fully-Automatic Double Yard-Counting Winding Machine is designed for high-precision and efficient winding operations, making it an essential tool for industries requiring accurate and automated yard-counting. With a power output of 4 kW, this machine operates at a speed of 280 RPM, ensuring smooth and consistent winding performance. It supports voltage ranges from 220V to 440V, making it versatile for different industrial power setups. The machine’s compact design, measuring 900×1400×1500 mm and weighing 100 kg, makes it suitable for various production environments.

This winding machine offers fully automated yard counting, reducing manual errors and improving efficiency. It operates within a voltage range of 220-440V, making it adaptable to different industrial power settings. With a 4 kW power rating, it delivers stable and energy-efficient performance. The high-speed operation of 280 RPM ensures quick and accurate winding, increasing productivity. It accommodates 50/210 size specifications, making it ideal for multiple winding applications. Built with a durable and compact structure, it measures 900×1400×1500 mm and weighs 100 kg, ensuring stability and long-term reliability.

The TKY-1 Fully-Automatic Double Yard-Counting Winding Machine enhances production efficiency by automating the winding process, reducing labor costs, and ensuring precision. With high-speed performance and energy-efficient operation, it significantly improves productivity while maintaining accuracy. Its robust design and high adaptability to different power sources make it a reliable choice for industrial applications. The compact and heavy-duty structure ensures long-lasting performance with minimal maintenance, making it a cost-effective investment for businesses looking to optimize their winding operations.

The TKY-1 Fully-Automatic Double Yard-Counting Winding Machine is widely used in textile and fabric manufacturing industries for precise yarn and thread winding. It is essential for rope and cord production facilities where accurate yard-counting is required. The machine is also utilized in wire and cable industries to ensure uniform and automated winding processes.

The machine o ers 2 to 12 models with a oor-panel design for smoother operation and reduced

vibration. Its high-strength faucet ensures durability and stable performance. The modular design

allows for easy Maintenance with universal parts. Electronic controls feature a self-test function for

quick issue detection. It includes automatic power outage memory, broken yarn self-stop, and

reduced tape scrap rates. Optional two- speed or servo motors with inch movement make debugging

easier. Key components, such as jacquard rope and electric parts, are made from imported materials

for superior quality.

No posts were found for provided query parameters.