Product Description:

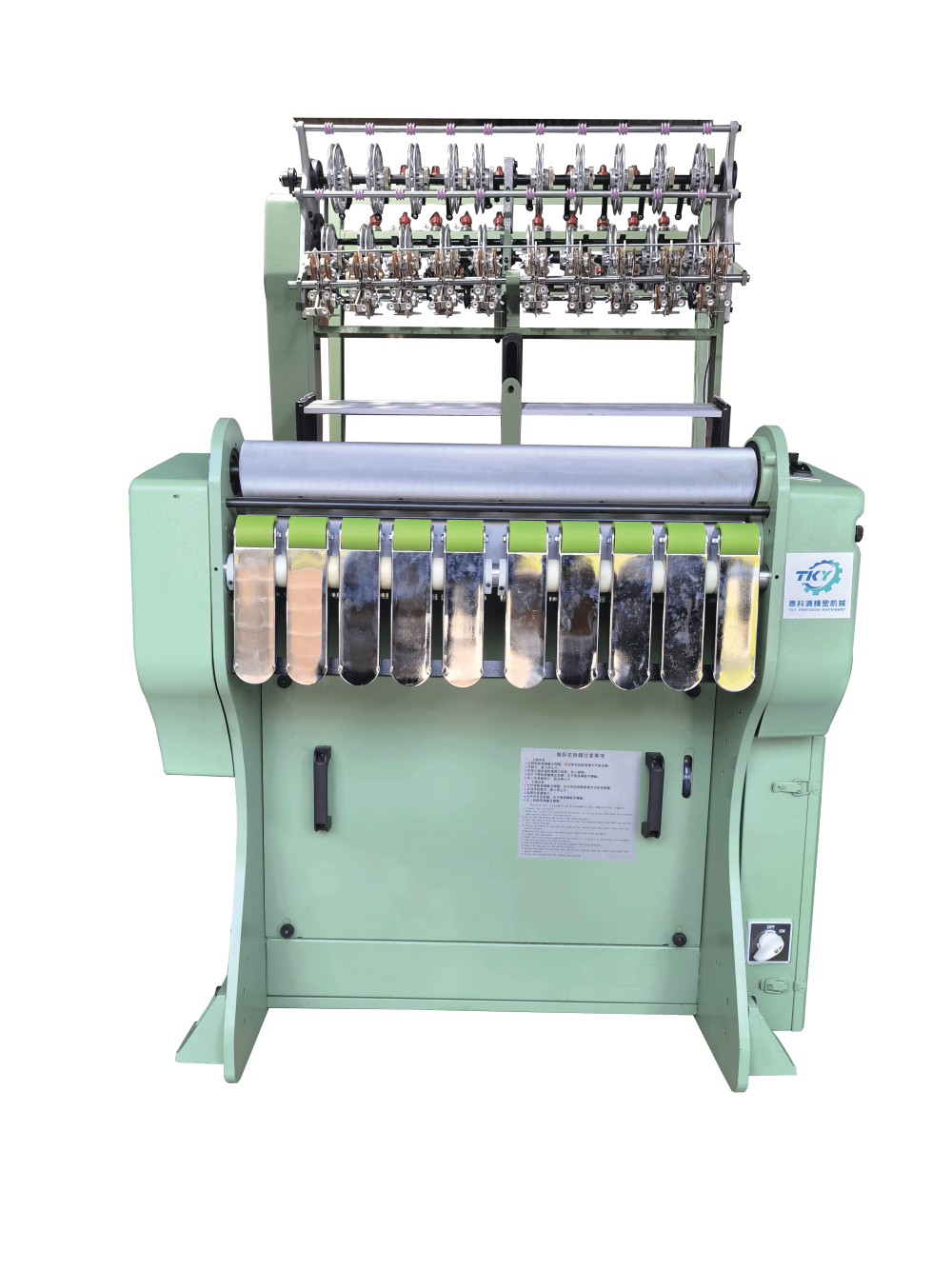

Our high-performance tape weaving machines are engineered to deliver exceptional efficiency and versatility, catering to a wide range of industrial applications. With multiple models available, ranging from 2/110 to 12/25, these machines are designed to meet diverse operational requirements.

Key Features:

These machines are perfect for manufacturers seeking reliable, efficient, and customizable solutions for tape weaving. Designed for long-term performance, they combine advanced features with user-friendly operation, making them a valuable addition to any production line.

Used for the production of unelastic narrow fabrics like luggage belt, plain elastic best, PP belt, Cotton Belt and son on; various specifications, productive, fast and High waving density; the latest design makes the weaving angle more reasonable and operation more user-friendly; output taps vary from 2 to 16 and maximum width from 3 mm to 210 mm

The machine o ers 2 to 12 models with a oor-panel design for smoother operation and reduced

vibration. Its high-strength faucet ensures durability and stable performance. The modular design

allows for easy Maintenance with universal parts. Electronic controls feature a self-test function for

quick issue detection. It includes automatic power outage memory, broken yarn self-stop, and

reduced tape scrap rates. Optional two- speed or servo motors with inch movement make debugging

easier. Key components, such as jacquard rope and electric parts, are made from imported materials

for superior quality.

No posts were found for provided query parameters.